CALICO COATINGS

We are service provider for

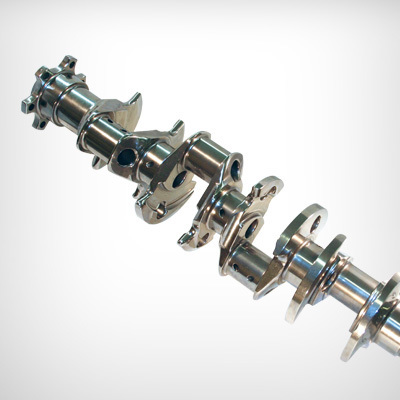

Camshafts Connecting Rods Lifters Pistons Valve Covers Valve Guides Valve Spring Shims Valve Springs Valves Wrist Pins Coatings View allCompany Profile

Calico Coatings solutions provide a wide range of protection and advantages to engineers and manufacturers worldwide. Many factors are taken into account to determine the effectiveness of our thin film coatings, the methods of application and the performance properties. Here you can find a list of our coatings and links to the detailed technical data sheets for each — including substrate, operating temperatures, applications and more.

Our History

Calico Coatings was founded by racers, for racers. Tracy Trotter, owner and a racer himself, set out to develop the industry's most technologically advanced coatings — with the ability to withstand the extreme conditions of high speed and engine wear. Calico quickly gained a reputation as a leader in high performance with race teams and engine builders to solve issues of friction, wear, heat and corrosion.

Trotter started the company with a little help from a special friend. “After working in the industry for several years I knew I could do this for myself. So, with the little savings I had and a small loan from my grandmother, I opened the doors of Calico Coatings.” Starting with only two employees, Calico has now grown to 40 employees, running two shifts in order to meet the growing demands of their customers.

For more than 20 years, the Calico team has worked relentlessly to maintain their reputation as the highest quality coating company in numerous industries in addition to racing. To remain on the cutting edge of coating technology they have also made advancements in thin films. “Our goal is to be the best in the coating business when it comes to quality,” said General Manager Jennifer Jenkins. “We have been blessed with an unbelievable team of people at Calico Coatings and they have been the reason for our success through the years.”

When many small businesses have struggled to keep afloat, Calico has been able to successfully navigate through the financial challenges of the recent years. In 2007, Calico expanded their operation by adding a laboratory facility dedicated to the research and development of new coatings, including diamond-like coatings. By the end of 2012, Calico combined their operations into their corporate headquarters. Then in 2019, an additional expansion to make room for more thin films machines is now a — a state-of-the art, 30,000 sq. ft. manufacturing and research facility located in Denver, NC.

Today, Calico’s performance coating knowledge and expertise is in demand across numerous high-performance industries including automotive/motorsports, the U.S. Military, aerospace, molds and dies, diesel engine, firearms and others. In these industries where performance is everything, Calico's coatings provide the needed edge for outstanding results. Calico’s arsenal of coatings that can withstand extreme pressure, reduce friction and wear include PECVD, DLC, PVD, TiN, ceramic, Teflon®, thermal, non-stick dry film lubricants and more.

CALICO COATINGS

Product or Service Spotlight

CALICO COATINGS

Videos and Tech Webinars

Segments of Market

Autocross Circle Track Diesel Racing Drag Racing Drifting Electric Vehicle Racing Formula/Single Seater Hill Climb Historic/Vintage Hot Rod Karting Land Speed Late Model Marine Racing Modified Motorcycle Racing Muscle Car Off-Road/Powersports Open-Wheel Rally Road Racing Sport Compact Sports Car/Endurance Stock Car Street/Strip Touring Car Tractor Pulling Truck RacingStart a Conversation

Share

Share