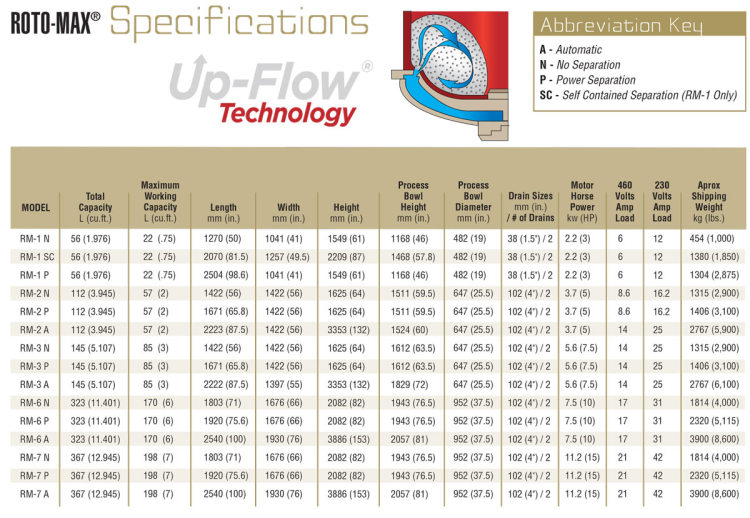

ROTO-MAX® High Energy Finishing

BROCHURE PDF

The Roto-Max® line are a series of centrifugal energy machines. The machine functions with a rotating disc or spinner in the bottom of the finishing chamber, and a stationary wall that the rotating disc meets with a precision gap.

The part and media mix is pushed outward on the rotating disc to the stationary sidewall. As the media is pushed, pressure builds and pushes the media and parts upward on the sidewall until the media falls back to the center of the rotating disc in a cyclonic action. This smooth and continuous motion produces an energy level up to 15 times greater than normal vibratory finishing systems.

Roto-Max® utilizes an Up Flow® compound and water system which cools the gap between the disc and the wear-ring or sidewall moving abrasive debris upward and out of the finishing chamber through a sidewall drain.

The Roto-Max® has a unique compound delivery system in the centrifugal disc market. The patented process is called Up Flow®. The name is derived from the compound being added to the bowl from under the media, and the resulting waste then exiting through a drain near the top of the media.

This Up Flow® technology, along with the adjustable seal gap height, greatly lengthen the life of the seal gap over other centrifugal disc machines. The greatest wear to the urethane lining are the particulates that come off the parts and media as it wears. With down flow compound, the particulates are sent through the lining.

Up Flow® technology significantly reduces the wear on the urethane, so can expect to have more ‘up time’ a with Roto-Max centrifugal disc than other centrifugal disc machines.

-Cycle Times up to 15 Times Faster than Vibratory Finishing.

-Improves Surfaces: Deburrs, Descales, Deflashes and Burnishes.

-Advanced Seal Design Prevents Intrusion of Smaller Parts and Media, thus Prolonging Tub and Rotor Life.

-Processes all Types of Material (Metal, ceramic, plastic and rubber)

-Wider Range of Surface Finishes are Attainable with a Given Media.